Laser Alignment Services

Our experience in condition-based monitoring has allowed us to witness first-hand that misalignment is responsible for a large proportion of issues and breakdowns in machinery and equipment, making accurate alignment essential.

Accurate Equipment Alignment on all Machinery

Most industries in the modern world recognise the need for accurate equipment alignment on all machinery both new and old, and the re-alignment process is generally included in regular maintenance work. Our history in condition-based monitoring has allowed us to witness first-hand that misalignment is responsible for a large proportion of issues and breakdowns in machinery and equipment, making accurate alignment essential.

What is Shaft Misalignment?

Machines need to be aligned in both the horizontal and vertical plane. The misalignment can be due to parallel or angular misalignment and is commonly a combination of both.

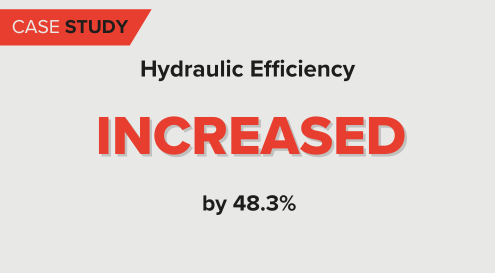

Shaft misalignment accounts for many expensive rotating machinery breakdowns, and accurately aligning shafts can significantly reduce the risk of unplanned downtime. In today’s challenging environment of reducing costs and optimising assets, the need for accurate shaft alignment is greater than ever.

Shaft alignment can be performed with different tools. The easiest way is to use a ruler or a straight edge over the two coupling halves or between two v-belt pulleys and align them by eye. As you can imagine this method of alignment is not very accurate and is dependent on the skill and expertise of the person completing the task.

A more traditional and accurate way of aligning two connecting shafts is to use mechanical dial test indicators (DTI’s). Generally, a skilled and experienced operator can obtain good and reliable measurements, but it takes time and patience.

Laser-Based Alignment

Machines need to be aligned in both the horizontal and vertical plane. The misalignment can be due to parallel or angular misalignment and is commonly a combination of both.

The best and most accurate way of aligning connecting shafts is to use laser-based alignment equipment. The range of equipment used enables us to laser align both shaft-to-shaft and v-belt pulley-to-pulley.

Our engineers have a vast amount of experience in alignment installations and have worked in all types of industry sectors supporting our clients to achieve optimum asset performance. The laser alignment equipment we use, delivers accurate and reliable results every time.

All our laser alignment equipment is serviced and calibrated on a regular basis ensuring that we maintain the highest level of accuracy when carrying out our inspections.

Contact Us Today

Whatever your project, we are here to provide fast, effective engineering solutions. Our specialist technical staff are happy to discuss any reactive or planned requirements you may have. We can inspect CAD drawings and files through to undertaking on-site visual inspections.