PROJECT OVERVIEW

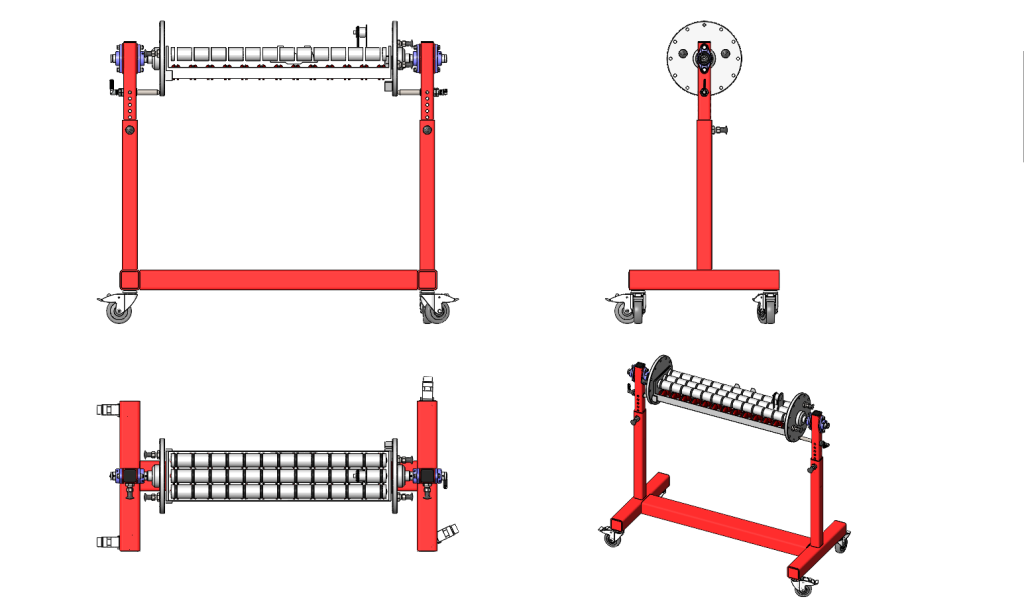

HAYLEY 247 DEXIS was commissioned to design and manufacture a PID Cassette Holding Turnover Unit for use in an e-commerce and retail warehouse environment. The goal was to create a solution that enhances both efficiency and workplace safety during the repair and handling of PID cassettes. This custom unit was specifically engineered to reduce manual handling strain and improve operational ergonomics, contributing to a safer and more streamlined workflow for warehouse technicians.

SCOPE OF WORK

The project began with a full CAD design of the turnover unit and all associated components. Our design engineers worked closely with the client to ensure the solution met all functional and safety requirements. Following the design phase, our in-house team handled the precision machining of all parts in accordance with the approved CAD drawings. Each component was manufactured with close attention to detail and build quality. Finally, the unit was fully assembled by our mechanical fitting team, ensuring the finished product matched design specifications and was ready for immediate deployment in the client’s facility.

KEY HIGHLIGHTS

- Purpose-built to improve health and safety and reduce manual handling risk

- Fully custom-engineered to meet specific requirements for PID cassette handling

- Delivered as a complete solution, including design, machining, and assembly

- Focused on ergonomics and durability to support daily warehouse operations

- Enhanced operational efficiency and technician safety

WHY CHOOSE HAYLEY 247 DEXIS?

The client chose HAYLEY 247 DEXIS for our reputation in delivering end-to-end engineering solutions. With expertise in CAD design, precision machining, and mechanical assembly, we provided a seamless service from concept through to completion. Our multidisciplinary capabilities, proven reliability, and commitment to quality made us the ideal partner for this warehouse enhancement project – Ensuring the client received a robust and effective solution, delivered with precision.