Electric Motor Services

- Industrial Gearbox Repairs and Refurbishment

- Machining Services

- Mechanical Services

- Industrial Gearbox Types

- Fabrication Services

- Pump Repair and Refurbishment

- New Product Sales

- Reverse Engineering

- Engineering Services Capacity List

- Electric Motor Services

Contact info:

Hayley Group Limited

Unit 58 Oldmedow Road,

Hardwick Ind Est,

Norfolk,

PE30 4LA

Tel: +44 (0)1553 770660

Email:

Hayley 247 offers quality electric motor repairs and rewinds.

We specialise in the repair of electrical motors from a wide variety of manufacture and can repair all types and sizes , ensuring the repair is carried out to a high standard to maintain the units efficiency.

Our team carry over 90 years of experience within the electrical motor trade.

All electrical motors which enter the workshop will undergo a specific electrical test, where specialist equipment will test the unit’s windings in order to analyse performance and detects any faults. We also offer full pump testing: Wet end and submersible with 2 7000L test tanks.

If a unit requires a rewind we can guarantee the motor will be rewound to class F/H specification and similarly, if the unit requires overhauling we will always install premium bearings.

We promise a quality standard throughout the entire repair process. For every unit which our engineers inspect, we compose a detailed in depth report which contains photographic evidence of the repair requirements this is then sent to the customer – This ensures transparency and open communication between us and our customers.

In addition, we also offer site services; Laser alignment, condition monitoring, on site engineers to assist with shutdowns, removing of units and/or reinstallation. We also have the resources to collect/deliver units to and from site.

We also hold a large range of WEG motors in stock as well as a large range of RADICON and TEC geared units ready for rapid deployment.

Capabilities over two sites (Dudley & King's Lynn):

- AC/DC motor repairs completed on and up to 50 tonnes

- AC/DC motors, pumps, geared units, fans, coil rewinds, servos

- ATEX-rated equipment repairs and rewinds

- Collection and delivery service

- Experienced team to help with on-site fault finding and reporting

- Detailed reporting containing photographic evidence of the repair requirements prior to commencement

- All repairs are fully-stripped, windings are tested using specialist equipment to ascertain if rewind is required

- All motors are rewound with class F/H specification material, new state-of-the-art burn-out oven is used to remove the old windings

- All pumps are fully wet tested and performance tested

- All units are returned with a test certificate and a protective wrapping

Two 7000L test tanks are used to prove that the seals, gaskets and O-rings are installed correctly. Providing our customers with the assurance that the pumps have been correctly repaired and are ready for immediate use.

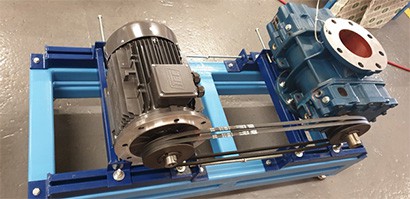

Our new bespoke test bed made for fully testing bare shaft lobe pump plus pumps and gearboxes.

AC 132kw 4 pole 3ph motor in the process of being rewound with Class H insulation we also repair servo motor, slip ring motors along with DC motors.

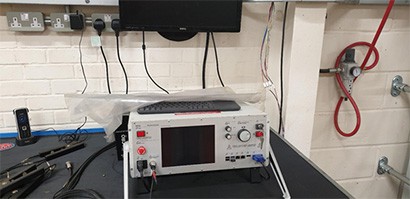

Motor analyser

This can be used on site for fault finding any size motor complete with a full report that can be sent via e mail and printed by the customer.

New state of art burnt out oven.

Gearbox going through its final checks before returning to the customer.