Industry: Heavy Industry / Emergency Machining

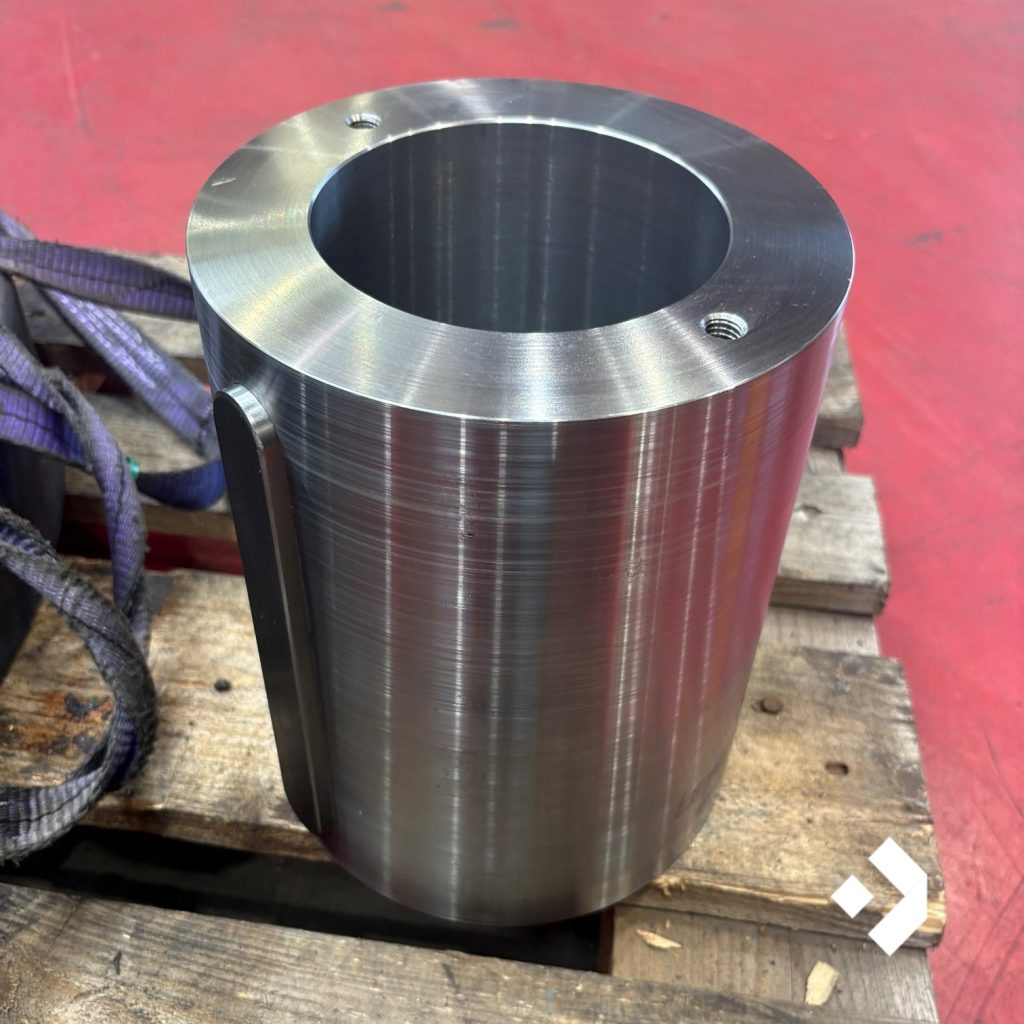

Component: Ø800mm Flanged Rigid Coupling

Client Requirement: Bore Reduction to Suit Replacement Shaft

THE CHALLENGE

A critical production asset was at risk when a client urgently required a bore size reduction on an Ø800mm flanged rigid coupling. The coupling needed to be modified to suit a free-issue shaft, and the entire job had to be completed in less than 24 hours to avoid costly downtime. With no replacement available and time ticking, the pressure was on to deliver a precise, reliable solution – fast.

THE SOLUTION

HAYLEY 247 DEXIS engineering team immediately got to work, executing a full in-house machining solution. Here’s how we delivered the modification with speed and precision:

- Bored out the coupling to accept a custom sleeve

- Machined an internal keyway to maintain drive integrity

- Manufactured a precision sleeve and key for accurate location

- Shrink-fitted the sleeve into the coupling bore for a secure fit

- Finish-machined the bore to the exact diameter of the free-issue shaft

- Slotted the internal keyway to match the new shaft requirements

All machining, fitting, and inspection were completed under one roof using our advanced turning, boring and keyway cutting equipment – ensuring full control over quality and turnaround time.

THE RESULT

Within 24 hours, the modified coupling was fully machined, tested, and ready for return to site. The client avoided unplanned downtime, saved on the cost of replacement components, and had a fully operational coupling back in service the next day. This project showcases HAYLEY 247 DEXIS ability to reliver emergency machining services with precision, speed, and zero compromise on quality – keeping our customers moving when it matters most.