Industry: Renewable / Biomass Energy

Client Priority: Critical failure – No spare unit available

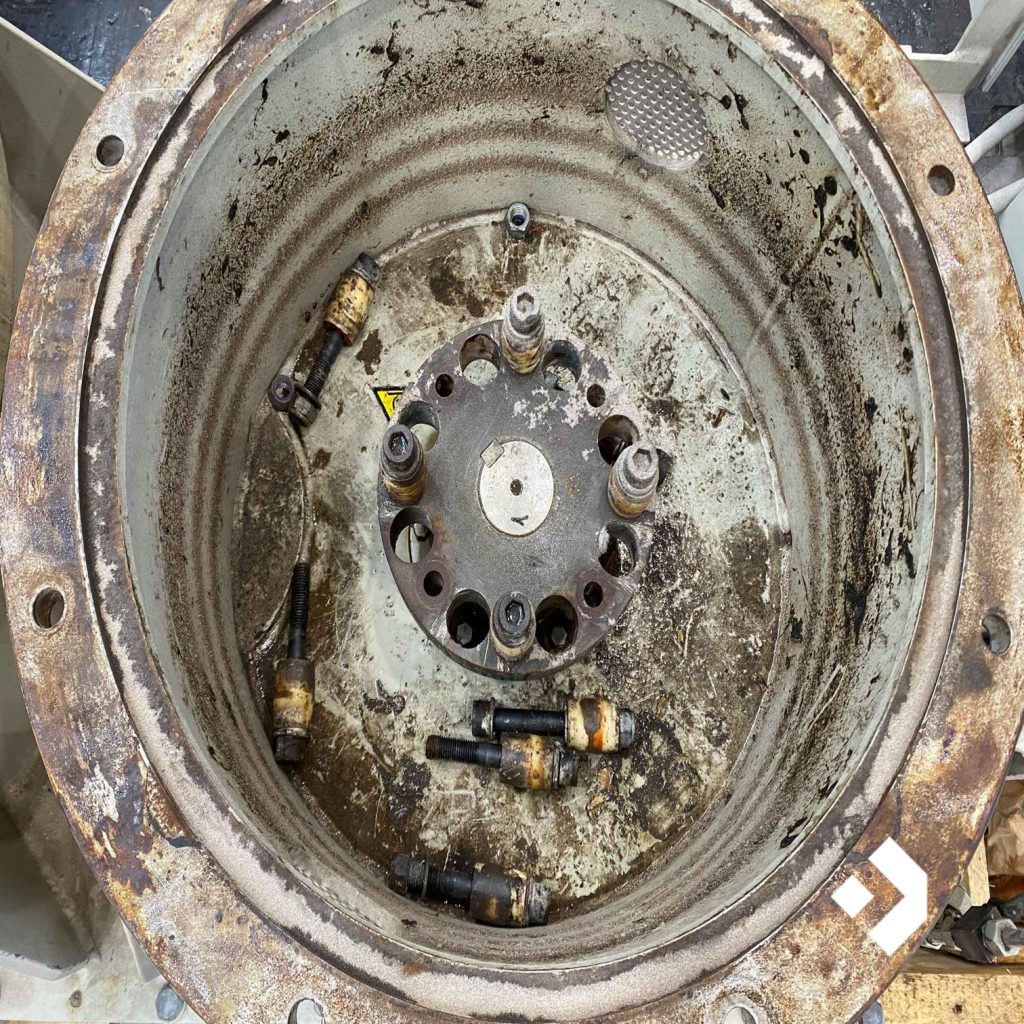

In May 2025, HAYLEY 247 DEXIS was contacted by a major client in the renewable energy sector following a critical failure of a Siwertell VG-2/355RF Twin Input Shaft Vertical Gearbox. This gearbox plays a vital role in a biomass energy plant’s material handling system, and with no spare unit on site, the pressure was on to restore functionality with minimal downtime.

The Challenge

The gearbox was collected on 21/05/2025 and immediately scheduled for a full engineering assessment. Our team was tasked with performing an urgent strip-down and inspection, uncovering the root causes of failure. A detailed report was completed by 11/06/2025, identifying severe internal wear caused by contaminated oil and poor lubrication—a major contributor to the breakdown.

Adding to the challenge was the fact that a replacement gearbox was not available, making an expedited repair the only viable solution to avoid costly disruption to energy production.

The Solution

Our engineering team quickly mobilised and commenced work on a full refurbishment program. This included:

- Complete strip-down and mechanical inspection

- Replacement of damaged bearings, seals, and lubrication components

- Repair of the output shaft bearing journal via precision sleeving

- Fabrication of a new fan cowling and supply of a new cooling fan motor

- Full clean, rebuild, and dynamic test run to verify performance

This comprehensive approach ensured all aspects of the gearbox were returned to OEM-standard condition, with upgrades made where necessary to improve future reliability.

Key Highlights

Urgency: The repair was treated as a high-priority emergency due to the absence of a spare unit

Root Cause: Contaminated lubrication was identified early, helping prevent future recurrence

In-House Expertise: All machining, fabrication, and rebuild work was completed internally, reducing lead time

Fast Turnaround: The estimated delivery of the fully refurbished unit was just 2–3 working weeks from report date

Why Choose HAYLEY 247 DEXIS

The client selected HAYLEY 247 DEXIS due to our proven track record of delivering rapid, high-quality repairs under pressure. Our ability to carry out full mechanical overhauls, precision component repairs, and custom fabrications in-house ensures minimal delays and maximum reliability—especially critical in sectors like renewable energy, where downtime is not an option.