THE SITUATION

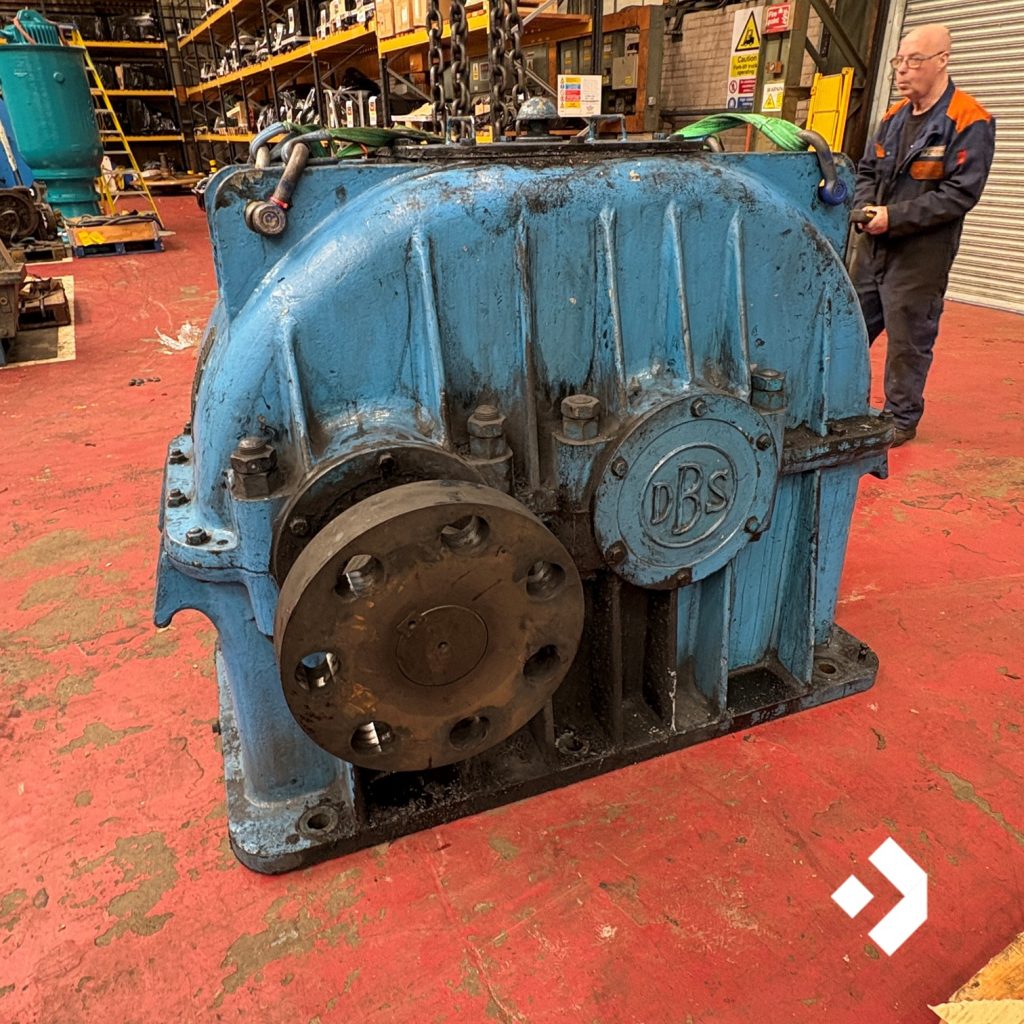

When a gearbox fails, production stops – and in high-demand industries like rubber manufacturing, every hour of downtime counts. HAYLEY 247 DEXIS was recently called in to support a customer facing exactly this challenge. A critical David Brown gearbox had suffered a sudden failure, bringing a key production line to a halt. The client needed a fast reliable repair, carried out to the highest engineering standards and delivered within days, not weeks.

THE SOLUTION

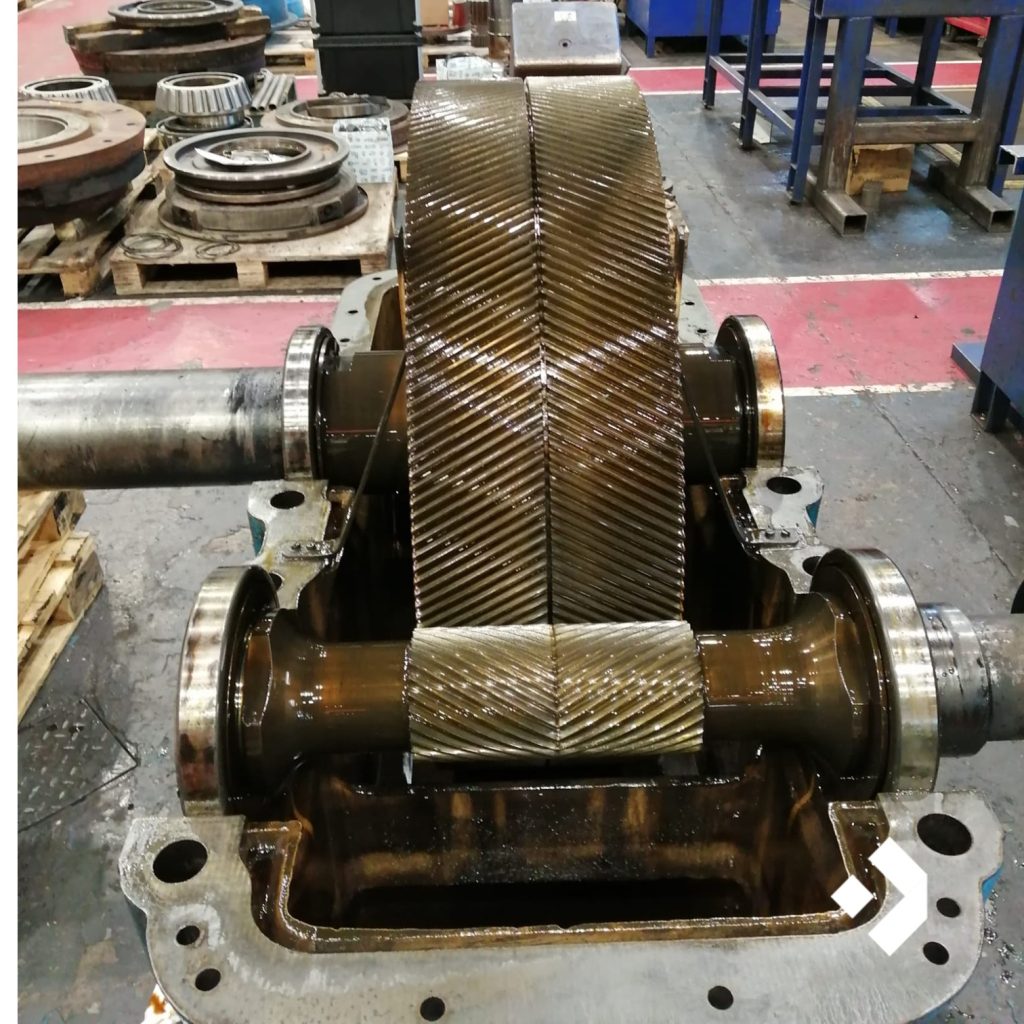

Our team immediately set to work, carrying out a comprehensive emergency overhaul to restore the gearbox to full working order. The repair included:

– Sleeving the input shaft seal area to restore the correct sealing surface

– Machining the labyrinth cover t suit the newly reclaimed shaft

– Replacing all bearings and dressing the existing gears to remove wear and ensure smooth running

– Sourcing, machining, and fitting a new Radicon coupling

– Manufacturing a new tapered gib head key for the output pinion

– Full gearbox rebuild, including a test run to verify performance

– Finished with a fresh, protective coat of paint

Despite the complexity of the work, the entire repair was completed within an impressive 4-5 day turnaround.

THE RESULT

The customer’s production line was back up and running quickly, with a fully restored gearbox built to deliver reliable performance. The rapid response, skilled machining, and efficient rebuild demonstrate HAYLEY 247 DEXIS ability to provide no-nonsense emergency repair solutions when they matter most.