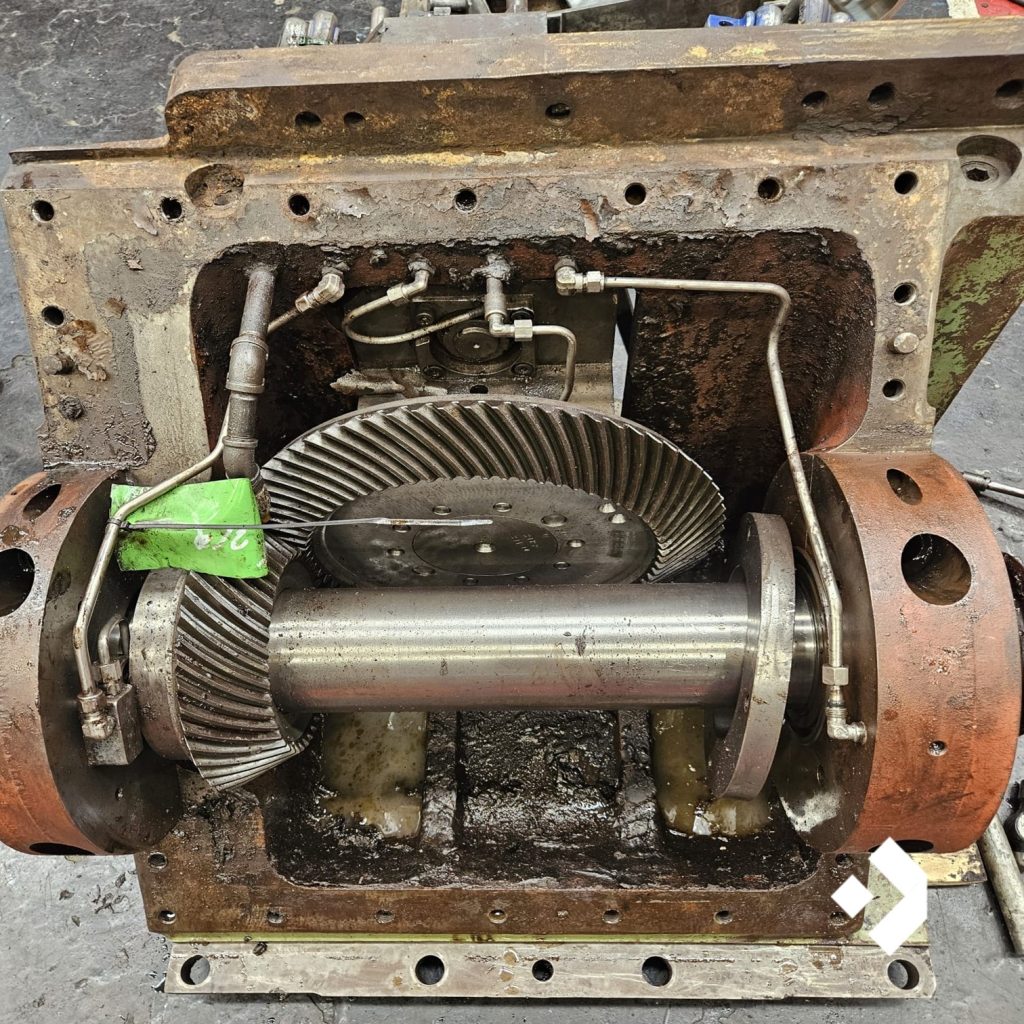

The Situation

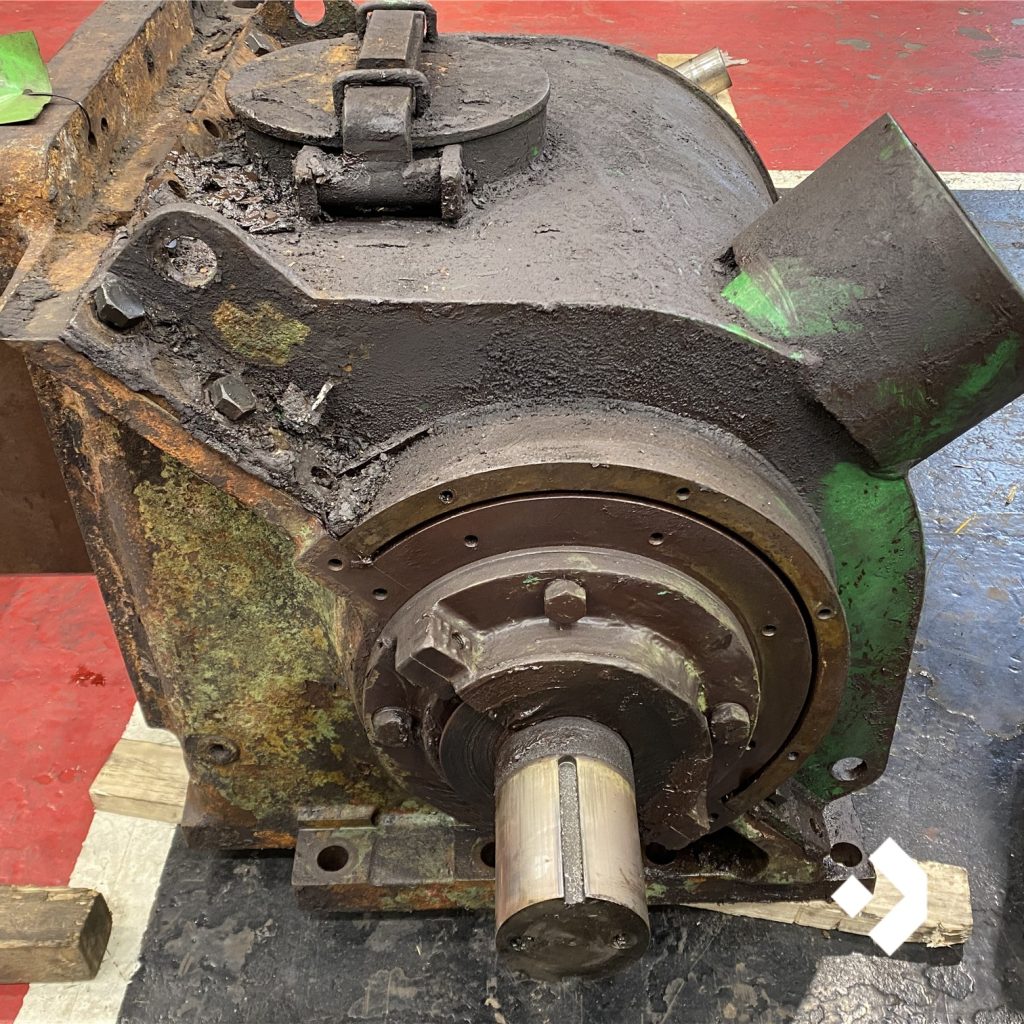

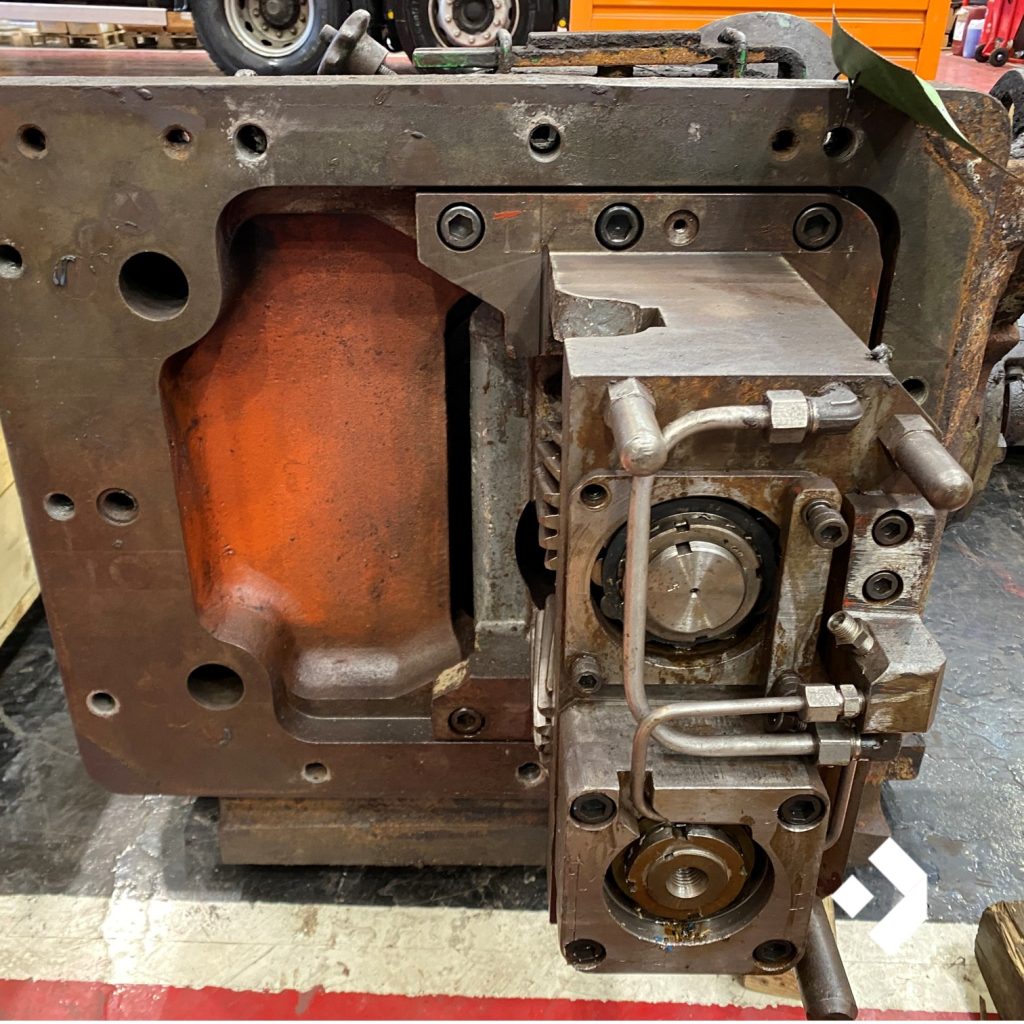

A Morgan Worcester helical/beval gearbox, operating within a demanding mill stand application, was removed from service due to deterioration an reduced reliability. Given the critical role of the gearbox in the drive system, the client required a complete inspection and refurbishment to restore performance and extend the unit’s service life. Upon arrival at our workshop, the gearbox showed signs of heavy external corrosion, along with internal wear that required immediate attention to prevent further damage and potential failure.

The Solution

The HAYLEY 247 DEXIS Engineering team carried out comprehensive overhaul, applying proven refurbishment techniques and precision engineering throughout the process.

The scope of work included:

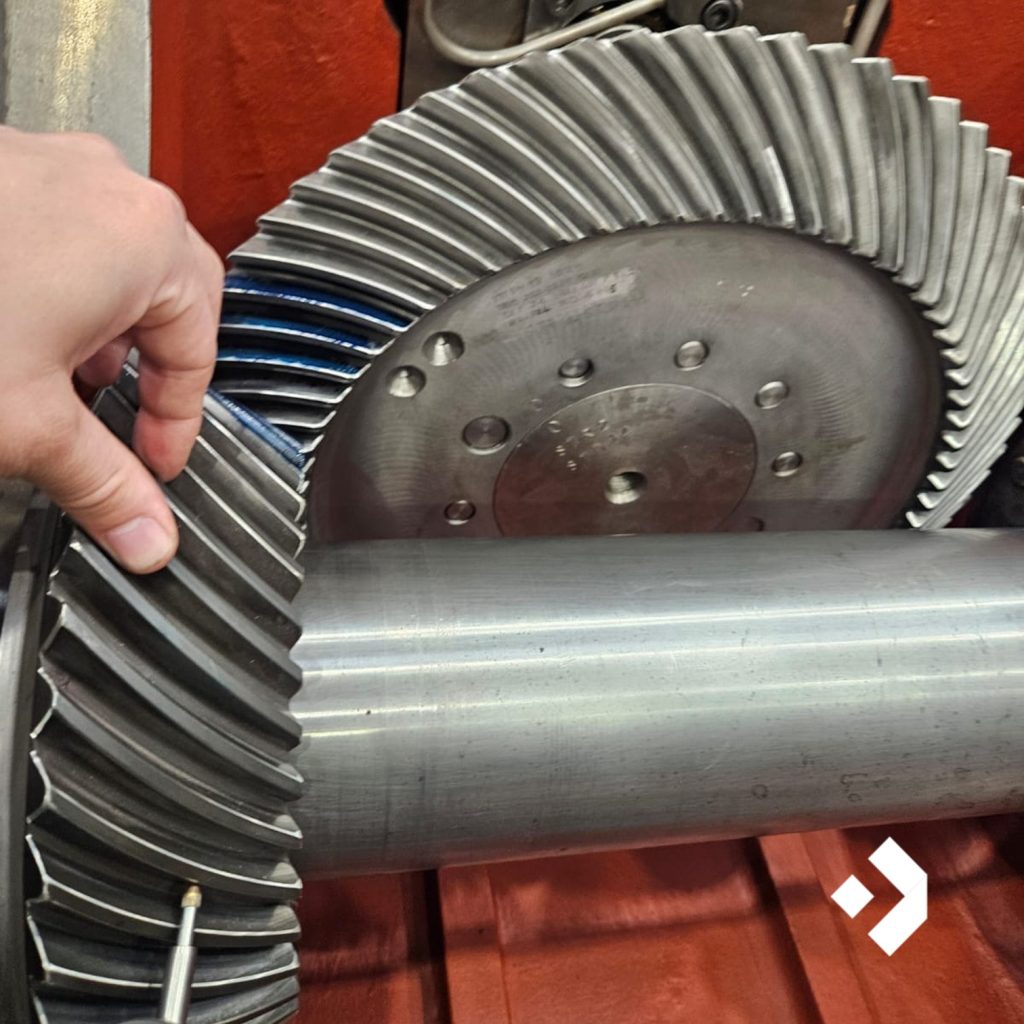

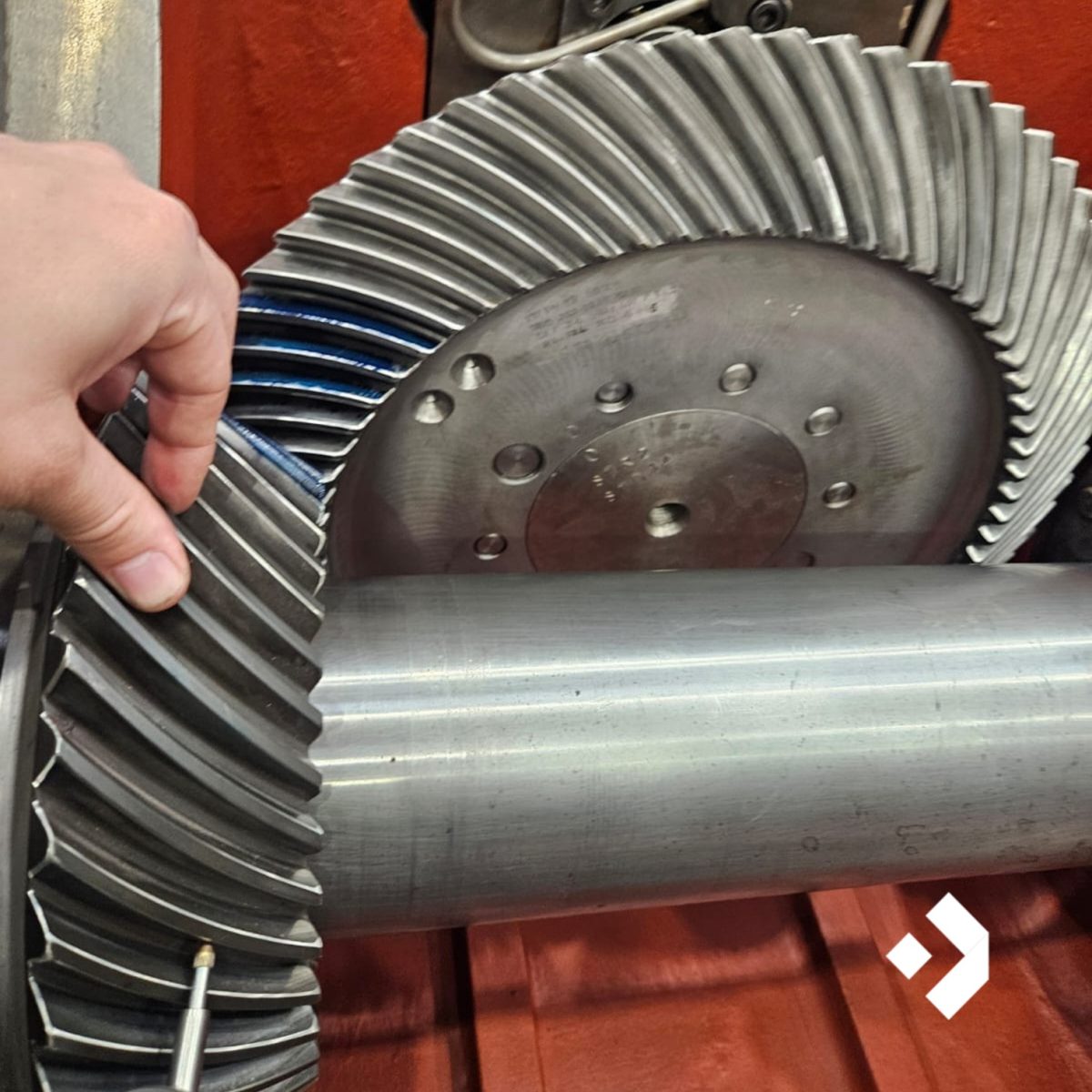

– Full strip-down and detailed inspection of all internal components

– Show blasting of the casing to remove corrosion and contamination

– Reclaiming a damaged bore using a precision-engineered sleeve

– Replacement of all bearings, seals, locknuts, and washers with new, high-quality components

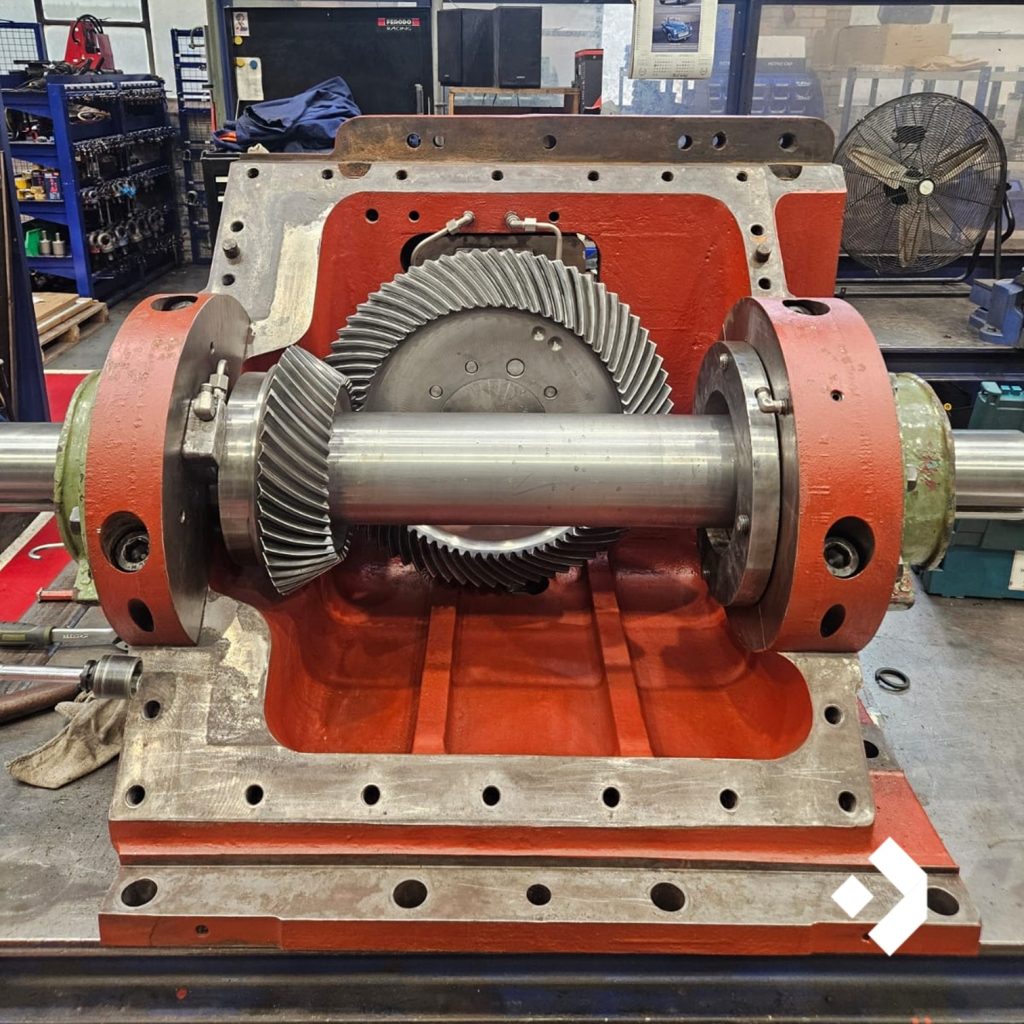

– Careful reassembly to specification, followed by a full test run to confirm smooth operation and performance

Every stage of the refurbishment was completed in-house under strict quality control, ensuring reliability and consistency.

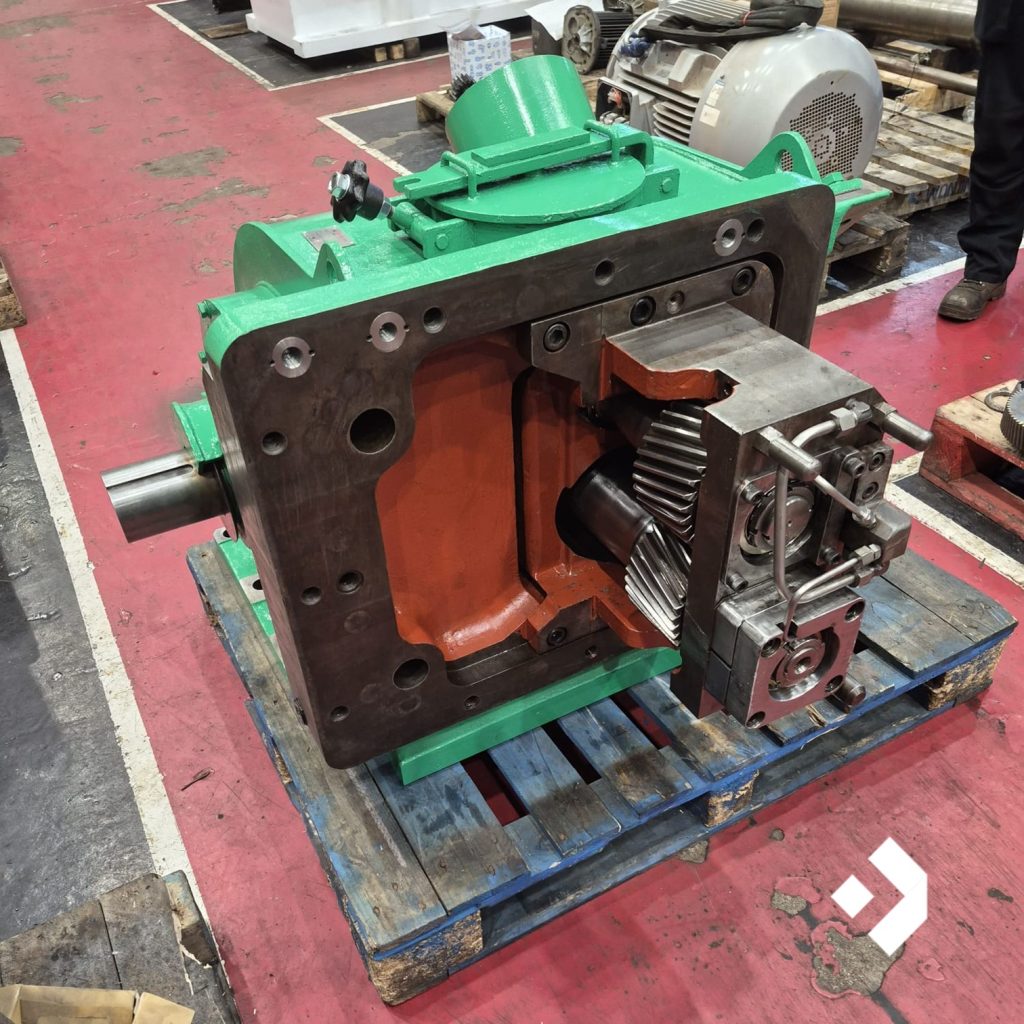

The Result

Following successful testing, the gearbox was finished, painted, and returned to site ready for service. The refurbishment restored the unit’s mechanical integrity and operational reliability, enabling it to return to a demanding production environment with confidence. This project demonstrates HAYLEY 247 DEXIS expertise in refurbishing critical drive equipment, helping customers avoid costly replacements and extended downtime.