PROJECT OVERVIEW

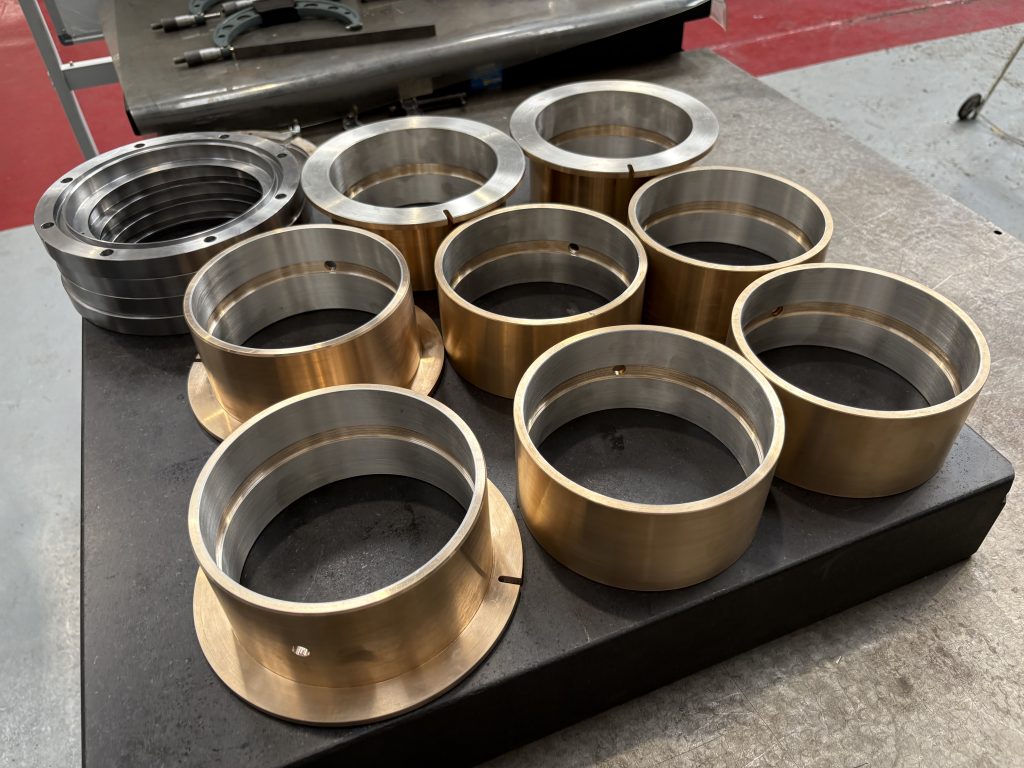

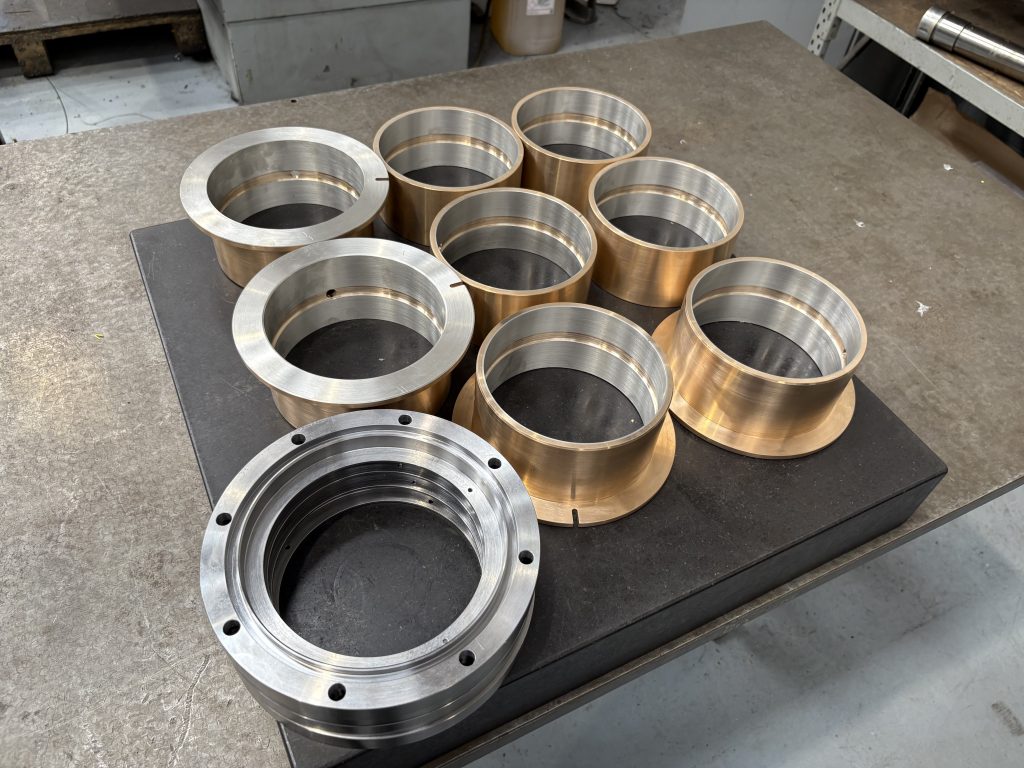

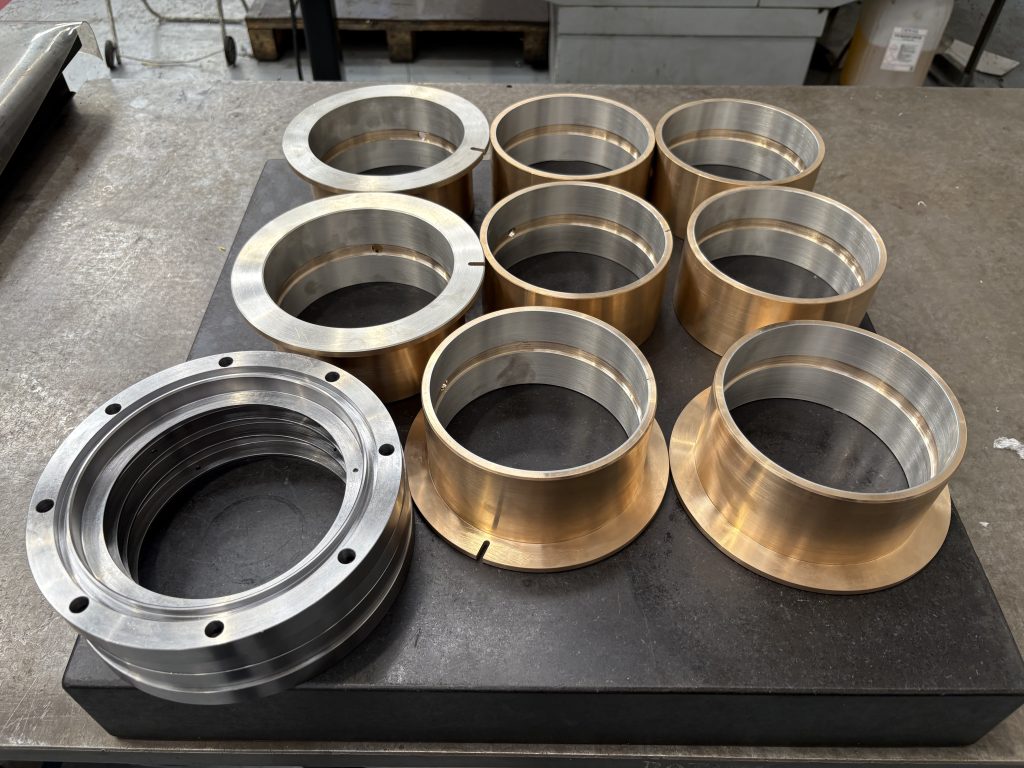

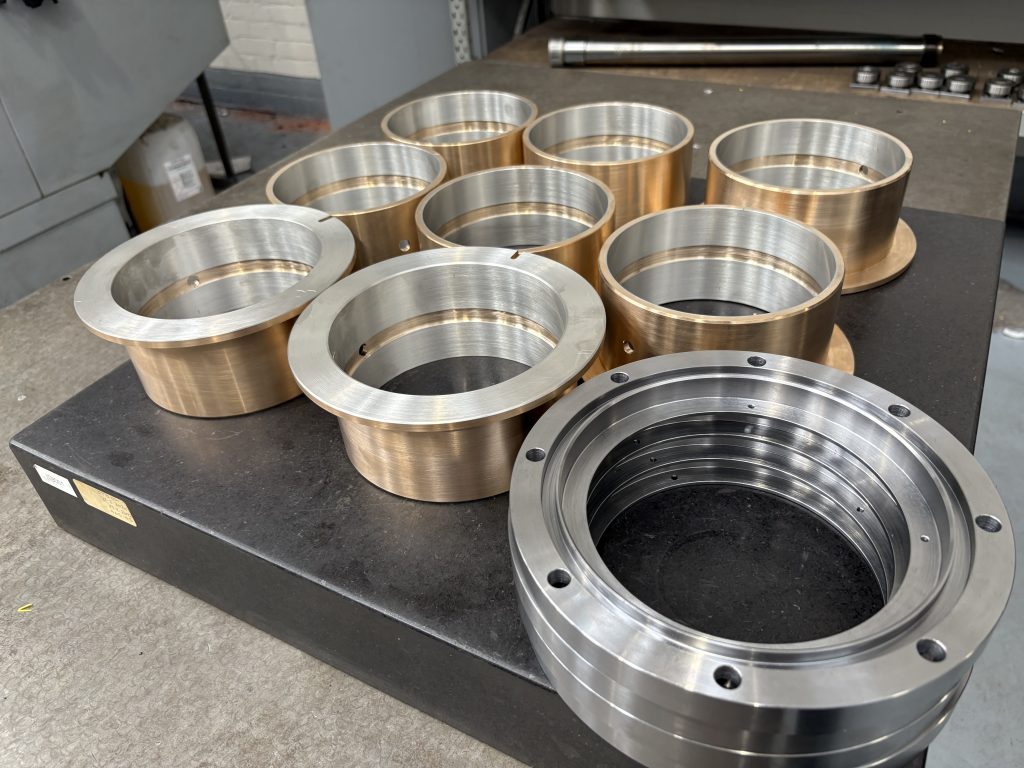

HAYLEY 247 DEXIS successfully manufactured high-precision white metal lined bronze bearings and seal retaining plates for use in critical nuclear applications. These components were produced in full compliance with technical drawings provided by the client, ensuring they meet the stringent requirements of nuclear industry standards.

SCOPE OF WORK

The Project encompassed several specialised manufacturing processes:

- CNC precision machining for exacting dimensional control

- Specialist white metaling process implementation

- Tight tolerance control throughout production

- Comprehensive quality assurance procedures

KEY HIGHLIGHTS

- Immaculate surface finish achieved on all components

- Complex white metaling process executed to perfection

- All components manufactured to strict nuclear industry standards

- Successful delivery of critical components for nuclear applications

WHY CHOOSE HAYLEY 247 DEXIS?

HAYLEY 247 DEXIS was selected for this project due to our proven track record in precision manufacturing and rapid turnaround times, especially in high-stakes sectors like nuclear. Our ability to deliver to tight tolerances, combined with in-house white metaling expertise and comprehensive quality assurance processes, makes us the preferred partner for demanding projects requiring exceptional precision and reliability.