PROJECT OVERVIEW

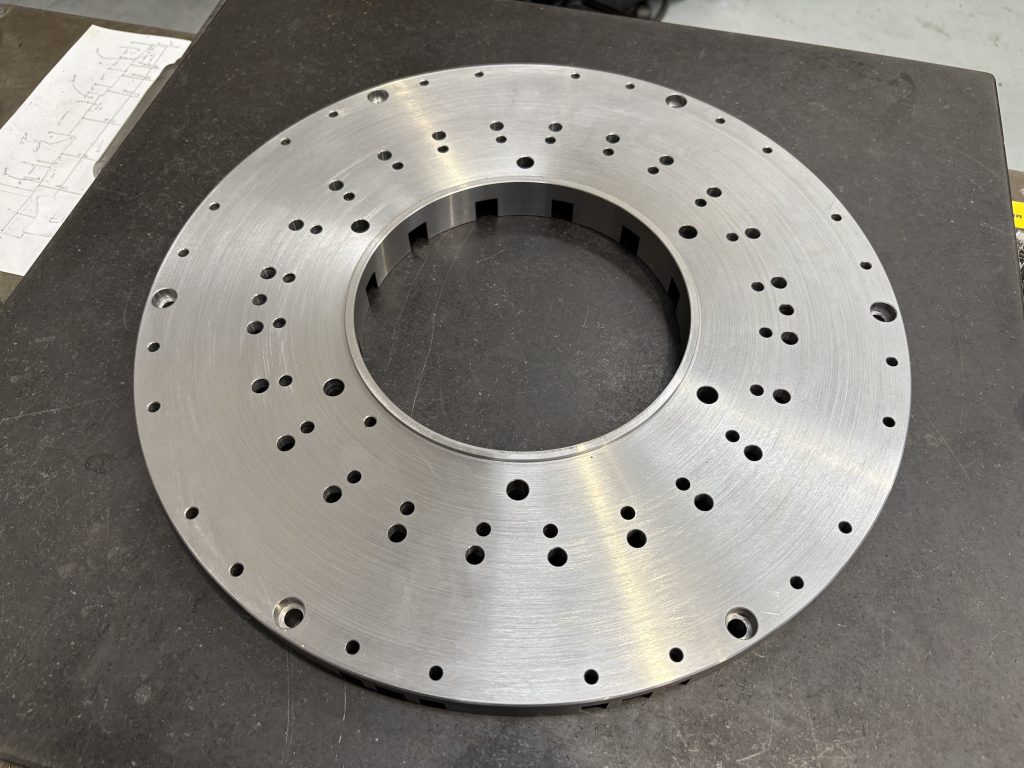

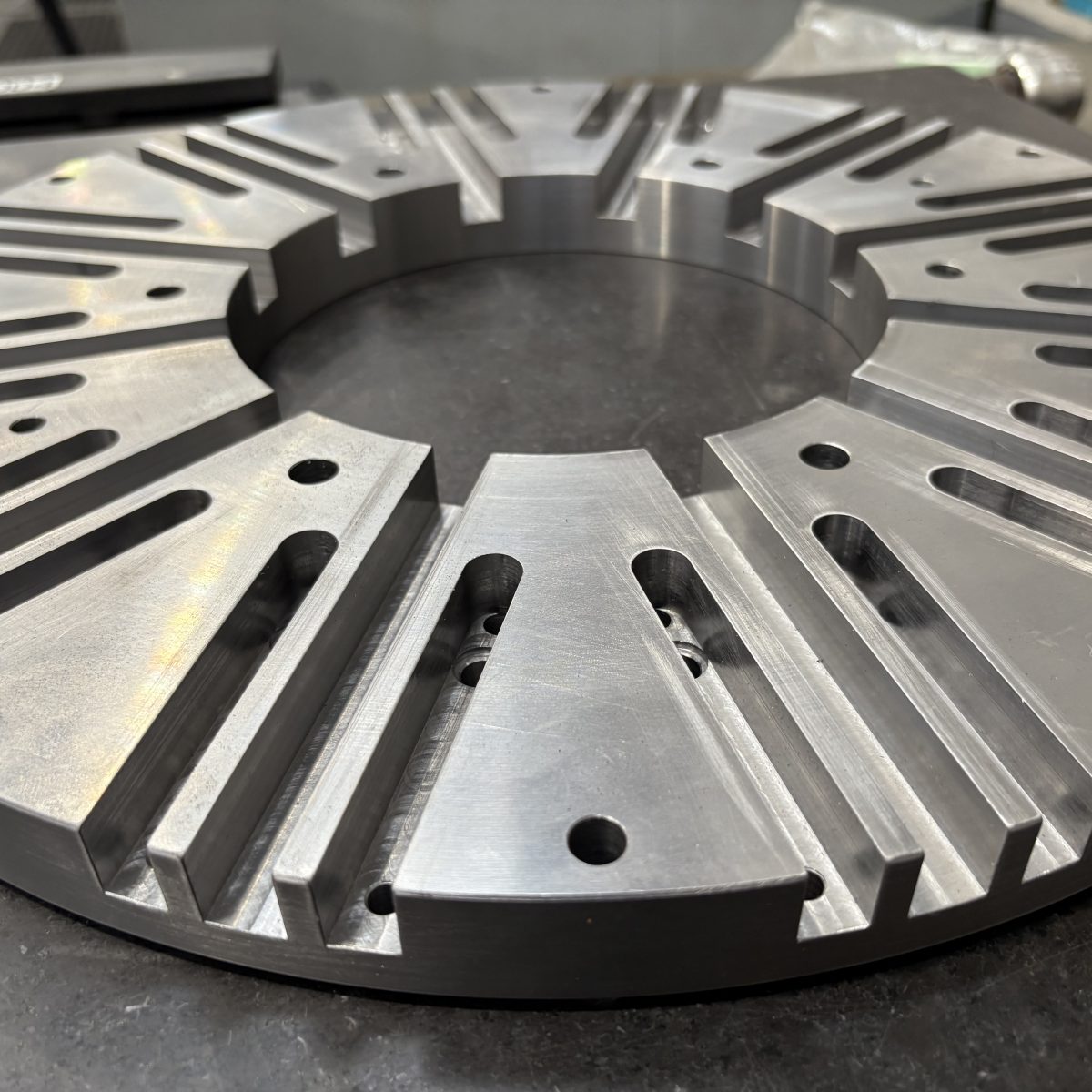

Our recent project involved the precision manufacture of Hopper Base Rings, crafted from high-quality tool steel according to the customer’s detailed drawings and specifications. This component required exacting standards and meticulous attention to detail throughout the manufacturing process to ensure optimal performance in its final application.

SCOPE OF WORK

The manufacturing process encompassed comprehensive CNC machining, including both turning and milling operations. Our team executed the project with precision, transforming raw tool steel into finished Hopper Base Rings that perfectly matched the customer’s requirements. Each component underwent rigorous quality control to verify dimensional accuracy and material integrity before delivery.

KEY HIGHLIGHTS

- Precision machining executed to exceptional standards

- Working to extremely tight tolerances of 0.01mm

- Production completed by time-served tool makers

- Craftsmen who take tremendous pride in their workmanship

- Component manufactured exactly to customer drawings and specifications

WHY CHOOSE HAYLEY 247 DEXIS?

When precision and quality are non-negotiable, manufacturers turn to HAYLEY 247 DEXIS for 3 primary reasons:

Trust: Our reputation for delivering components that meet or exceed specifications has earned us the confidence of clients across the manufacturing sector.

Capacity: Our facility is equipped to handle projects of various scales without compromising on quality or delivery timeframes

Capabilities: Our team consists of time-served tool makes whose craftsmanship sets the standard in the industry. Their expertise in working with tool steel and achieving tolerances as precise as 0.01mm makes us the ideal partner for amending manufacturing projects.