The Problem

Two Cone Mounting Plate Assemblies, each measuring up to 2 metres in diameter and weighing around 3 tonnes, had suffered extensive wear. The hubs, ribs, and shafts were no longer serviceable, and the assemblies required a full refurbishment to return them to operational condition.

The Solution

We carried out a comprehensive reclamation process, ensuring precision engineering at every stage:

– Stripped down and inspected assemblies to identify repair requirements

– Removed worn hubs and ribs from the cone mounting plates

– Manufactured, fabricated, and welded new hubs and ribs onto the existing plates

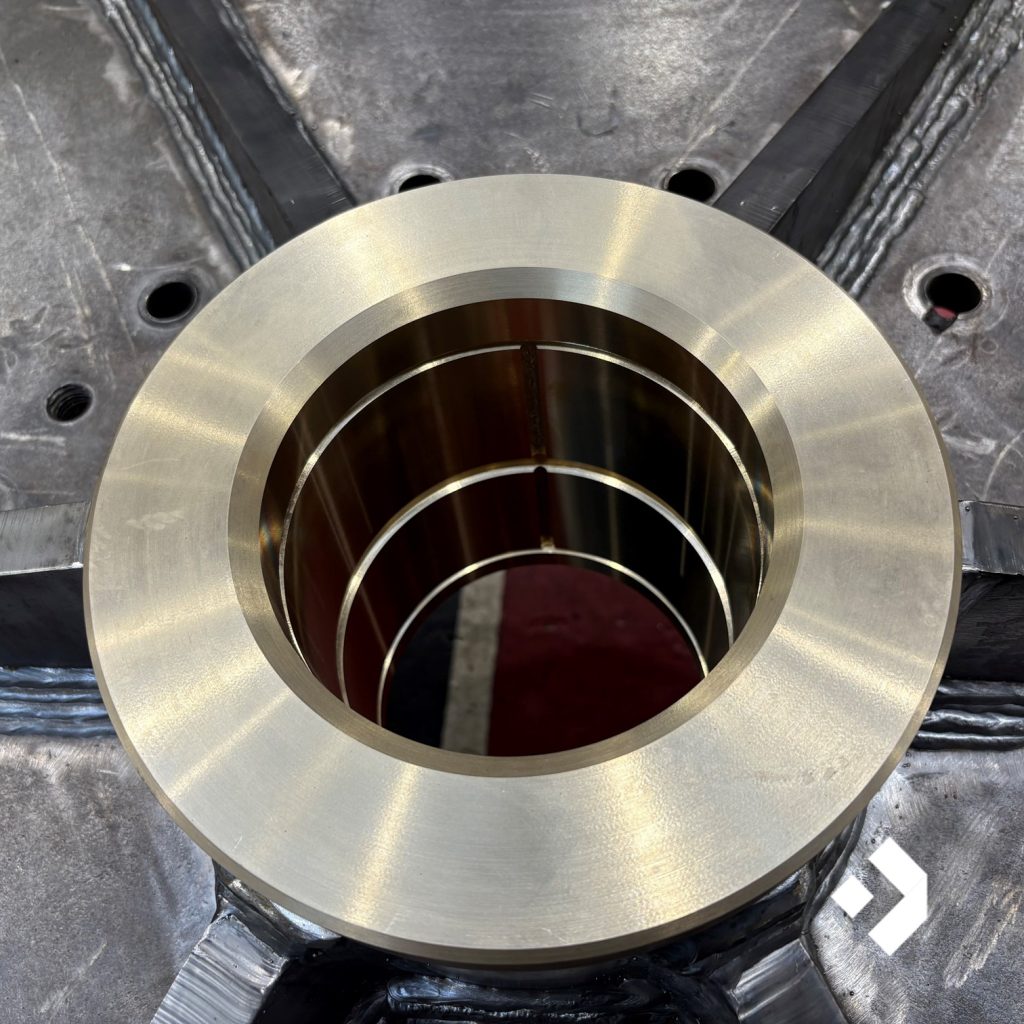

– Manufactured and installed bronze sleeves using advanced cryogenic fitting techniques

– Manufactured and installed brand-new shafts

– Fully rebuilt the assemblies to original specification

The Result

The refurbished assemblies are now restored to peak condition, both structurally and visually. This project demonstrates our ability to revive large, heavy-duty components to a high standard — extending their service life, reducing costs, and delivering reliable performance.