The Situation

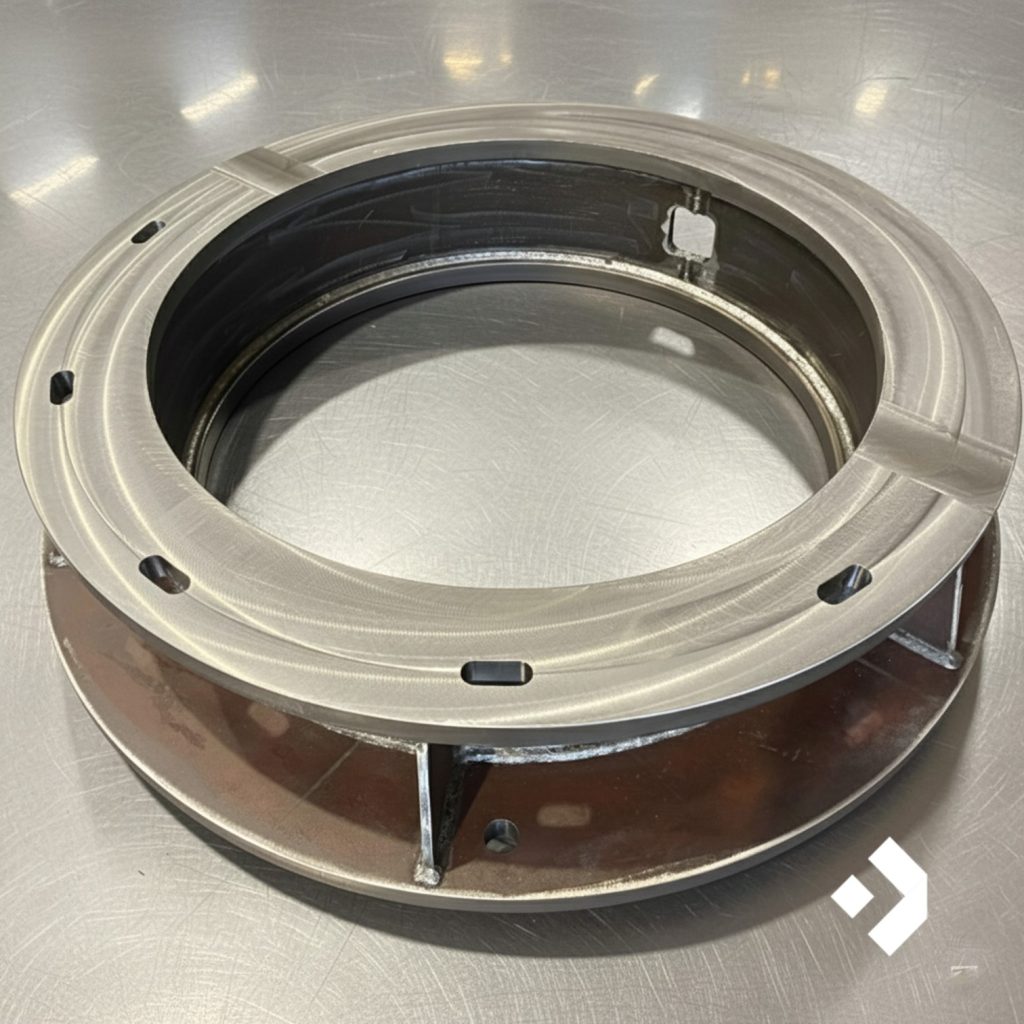

When a critical pump base plate at a client’s facility began showing significant wear, the risk of continued operation became clear. Years of heavy use and vibration had led to fatigue and structural distortion — threatening both reliability and alignment of connected equipment. With the pump central to daily production, downtime wasn’t an option. The client required a complete replacement, but not just a like-for-like swap. They needed a stronger, more durable solution, engineered to extend service life — and they needed it fast. Recognising the urgency, the Hayley 24/7 engineering team was tasked with delivering a full end-to-end solution: remove, redesign, rebuild, and reinstall — all within a single week.

The Solution

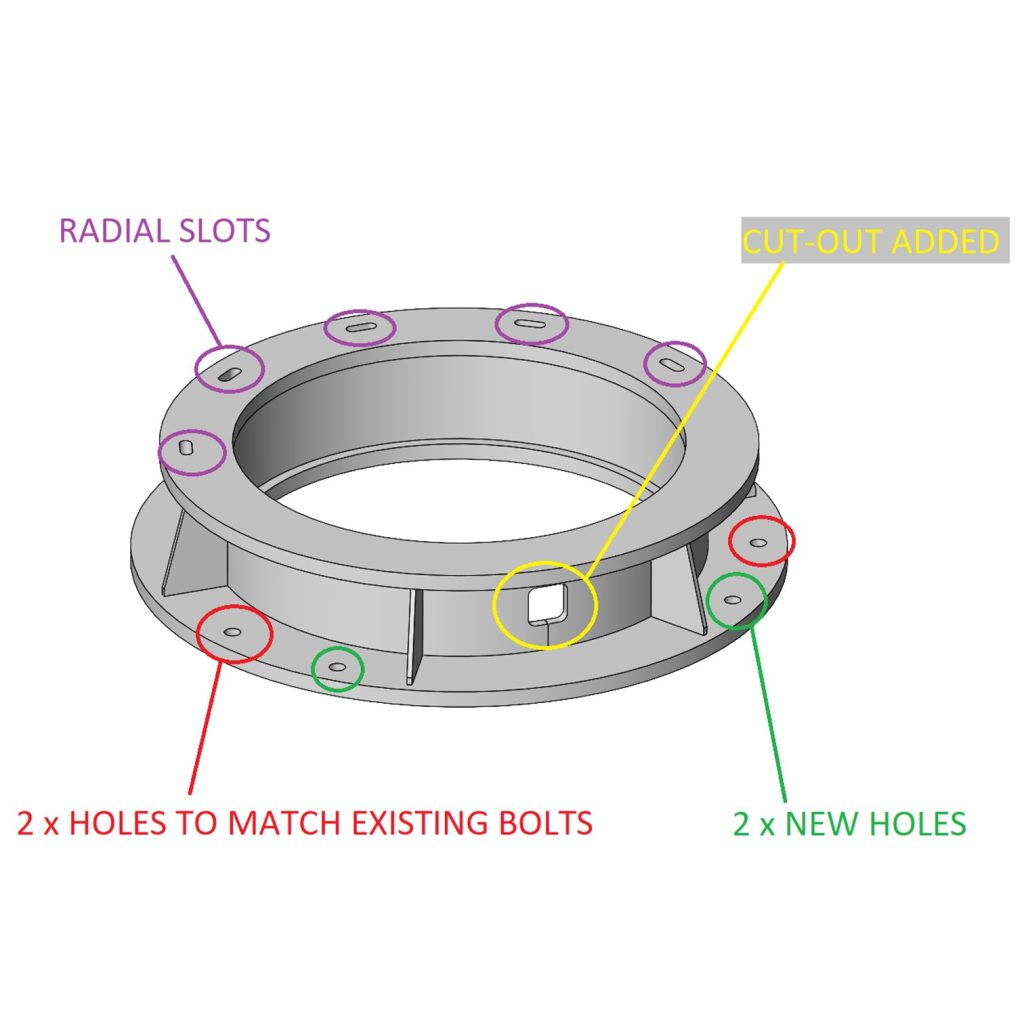

Hayley 24/7’s multi-skilled team immediately mobilised to site, removing the worn base plate and carrying out a comprehensive dimensional inspection to capture critical data for redesign. Using advanced reverse-engineering methods, our design engineers developed a structurally enhanced version of the plate, optimised to handle greater load capacity and resist vibration fatigue. With design approved, we moved swiftly into production.

– High-grade materials were sourced the same day

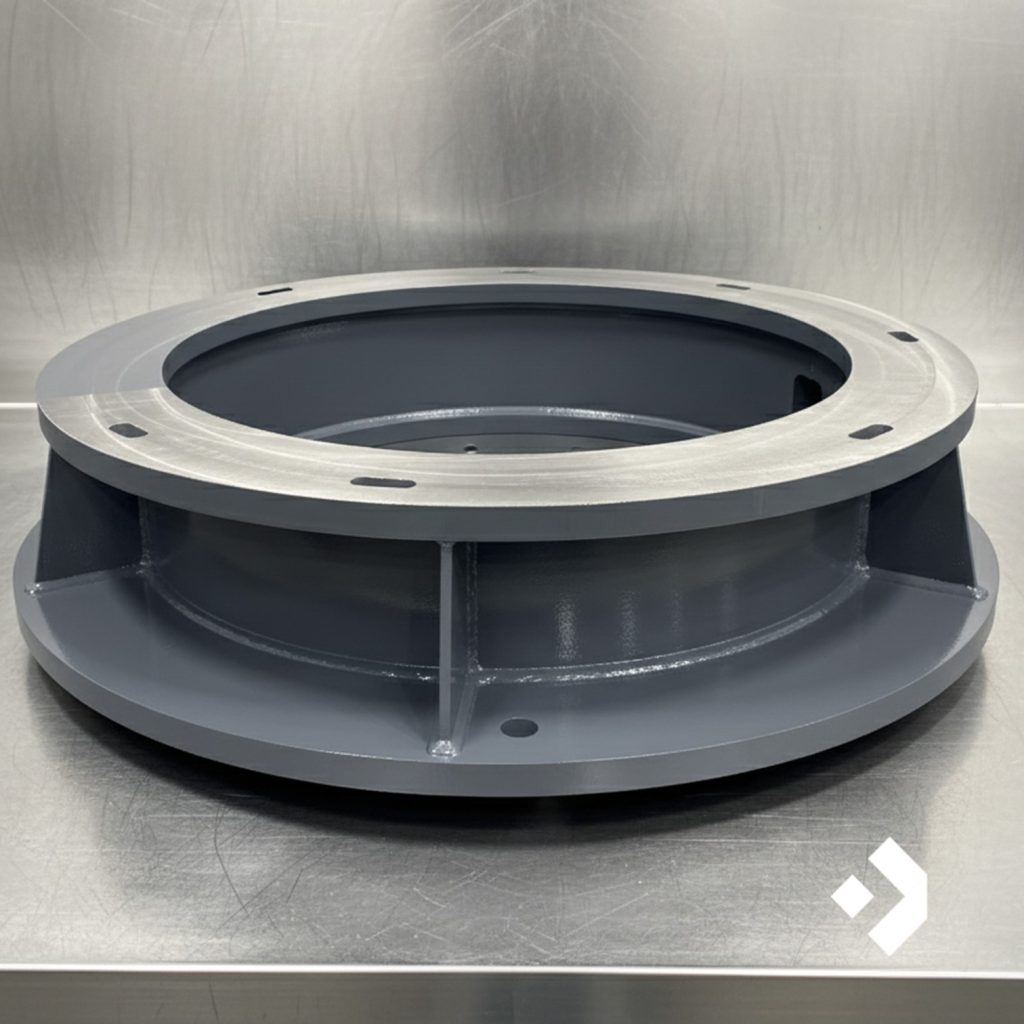

– The new base plate was fabricated, welded, and precision-machined to exact tolerances

– A protective paint finish was applied to ensure long-term corrosion resistance and a clean, professional appearance

– Finally, the completed unit was reinstalled and aligned on-site, ready for immediate operation

From initial removal to full installation, the entire process was completed within just seven days — a testament to Hayley 24/7’s capability, coordination, and speed.

The Result

The new pump base plate delivered more than just a replacement — it represented an engineering upgrade. The improved design and fabrication have increased the system’s structural integrity, reliability, and long-term performance. For the client, downtime was kept to an absolute minimum, and production resumed without delay. This project stands as a clear example of Hayley 24/7’s end-to-end engineering expertise — combining precision, innovation, and responsiveness to keep industry moving. When critical components fail, Hayley 24/7 is ready to deliver solutions that are fast, reliable, and built to last.