Project Overview

HAYLEY 247 DEXIS was urgently tasked with supporting a critical breakdown situation in the defence industry. The job required the rapid manufacture of threaded stud and nut assemblies for a high-pressure application, with the goal of preventing costly downtime in a tightly regulated environment. Working to an accelerated schedule, the project was completed and delivered within just 2 working days from the initial request.

Scope Of Work

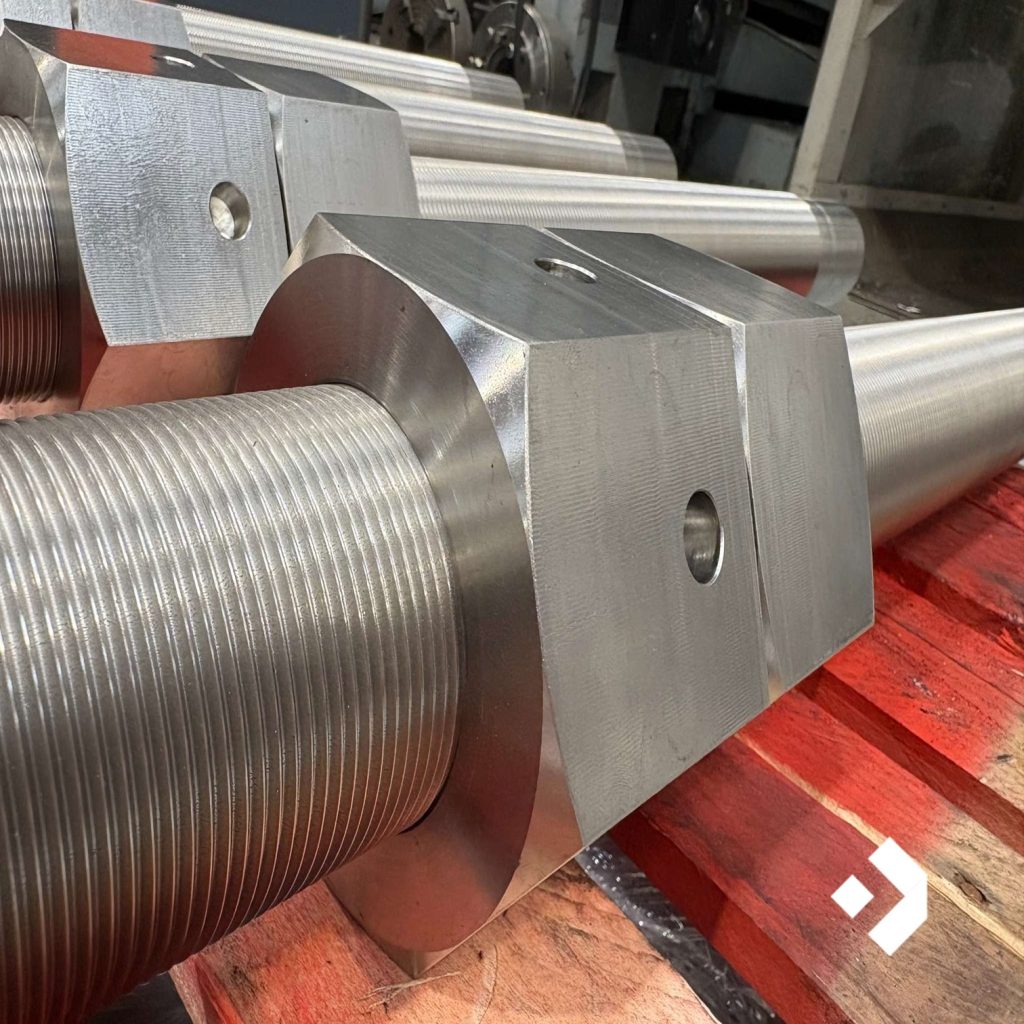

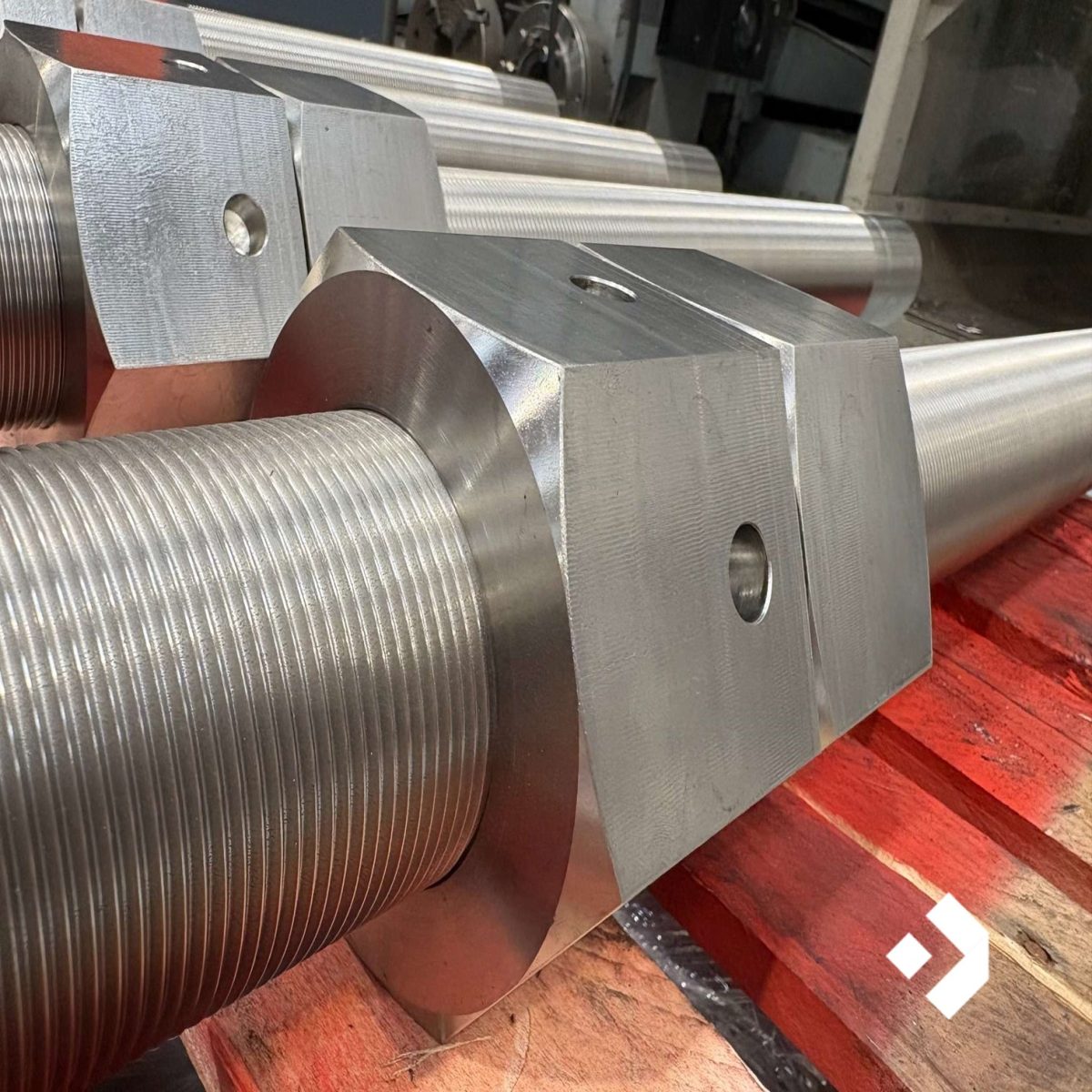

The assignment began with reverse engineering the required components, as original specifications were unavailable. Our engineers accurately reproduced the design using advanced inspection techniques to ensure dimensional accuracy. We then moved immediately into precision machining, producing fine pitch threaded stud and nut assemblies (3-1/4″ UNF) to meet the strict tolerances and mechanical performance required for defence operations. All work was completed in-house, under tight quality controls and in compliance with defence standards.

Key Highlights

- Emergency turnaround completed in 2 working days

- Reverse engineered without original drawings

- Precision machining of 3-1/4″ UNF fine pitch threads

- Delivered with full quality assurance under defence industry standards

- Averted extended downtime for a critical process

Why Choose HAYLEY 247 DEXIS?

The client turned to HAYLEY 247 DEXIS for our proven ability to deliver under pressure. Known for our rapid response and technical versatility, we specialise in solving urgent breakdowns with high-quality, fully engineered solutions. With in-house capabilities spanning reverse engineering, CNC machining, and component testing, we deliver precision – and peace of mind – exactly when it’s needed most.