Project Overview

HAYLEY 247 DEXIS recently completed a comprehensive gearbox overhaul for a key client in the aluminium manufacturing sector. The gearbox, which powers an aluminium scalper machine, was serviced during a planned outage—an ideal window for preventative maintenance and performance restoration. This project reflects the company’s commitment to delivering responsive, high-quality engineering solutions that keep UK manufacturing moving.

The Problem

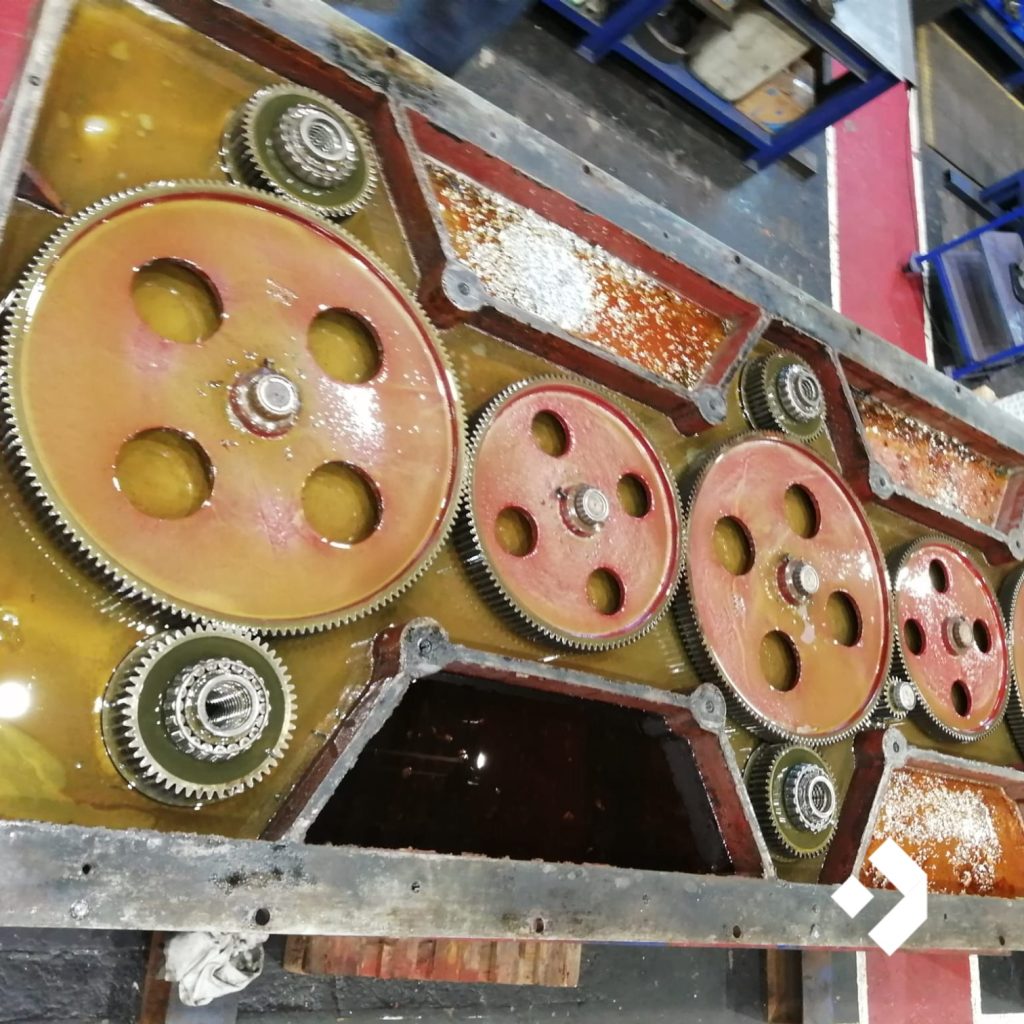

Upon strip-down of the gearbox, the engineering team discovered significant aluminium deposits and swarf inside the casing. These contaminants had begun to interfere with the gearbox’s performance, threatening the reliability of the scalper machine and potentially leading to costly downtime if left unresolved.

The Solution

HAYLEY 247 DEXIS carried out a full technical assessment and implemented a multi-faceted repair strategy. First, all gear teeth were carefully dressed to ensure they could be reused without compromising performance. The team then reverse engineered the gearbox internals, creating detailed specifications to support future spare part supply—an important step in long-term asset management.

All bearings and seals were replaced, and the team conducted precise checks on gear contact patterns and backlash, ensuring optimal alignment and smooth operation. Additional work included reconditioning trapezoidal threads and mating gear bores, restoring critical interfaces within the gearbox.

During inspection, a crack was identified in the original cast input pulley. Rather than risking failure, the team manufactured a new pulley to exact specifications. Finally, the gearbox underwent full testing to confirm it met production requirements before being returned to the client.

The Result

The gearbox was successfully returned to service, fully tested and aligned with the client’s production needs. The project not only resolved immediate performance issues but also laid the groundwork for future maintenance and part replacement. The client was highly satisfied, and the project reinforced Lamond and Murray’s reputation for precision engineering and proactive support in the UK manufacturing sector.